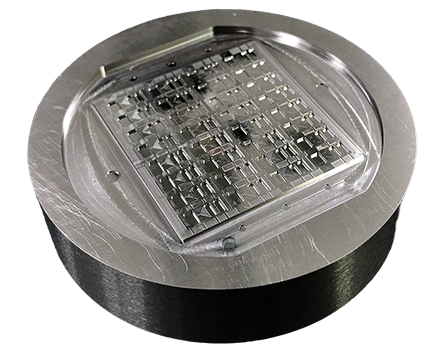

Over 25 Years of Expertise in Vacuum Thin Film Coating

We are a technology-driven coating solutions provider offering in-house designed equipment and coating services. Our proprietary FCVA, PVD, and PECVD thin film technologies deliver high hardness, superior adhesion, and environmentally friendly surface solutions for tribological, decorative, and energy-related applications across multiple industries.

Get In Touch