-

FCVA

Excellent coating performance

-

Carbon or Metal

SourceExtend coating types

-

Large Vacuum

Gate ValveHigh throughput rate

-

Modular Design

Flexible to increase to decrease

number of chambers -

Customisable

Substrate HolderThat fits your needs

-

User Friendly

Control PanelEasy to operate and control

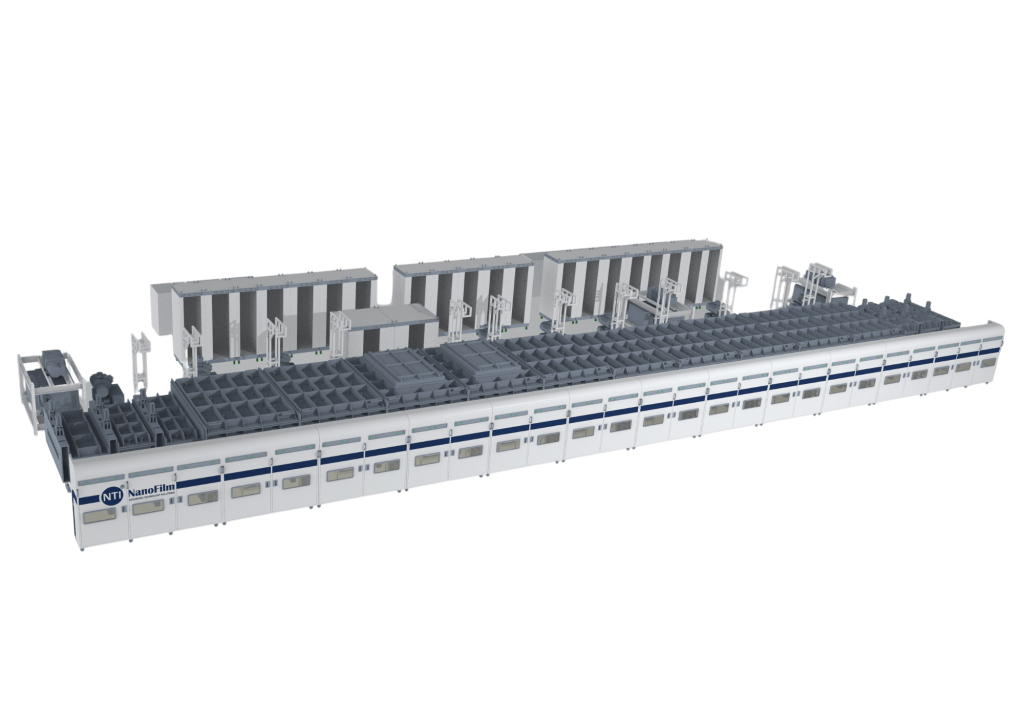

Coating Equitment

FCVA Hybrid In-line System

Based on modular design, the system is flexible to increase or decrease number of chambers according to your needs. Each process chamber is equipped with 1 pair of of FCVA (Filtered Cathodic Vacuum Arc) source and 1 pair Linear Sputtering source or Cylindrical Rotating Sputter source. The system is plasma based, highly configurable and produces highly uniformed coating with wide range of composite. It is specially designed with large vacuum gate valve. It has throughput up to 5 minutes per batch and able to continually operate for more than 3 days (72 hrs).

Get a Quote