Frequently Asked Questions

-

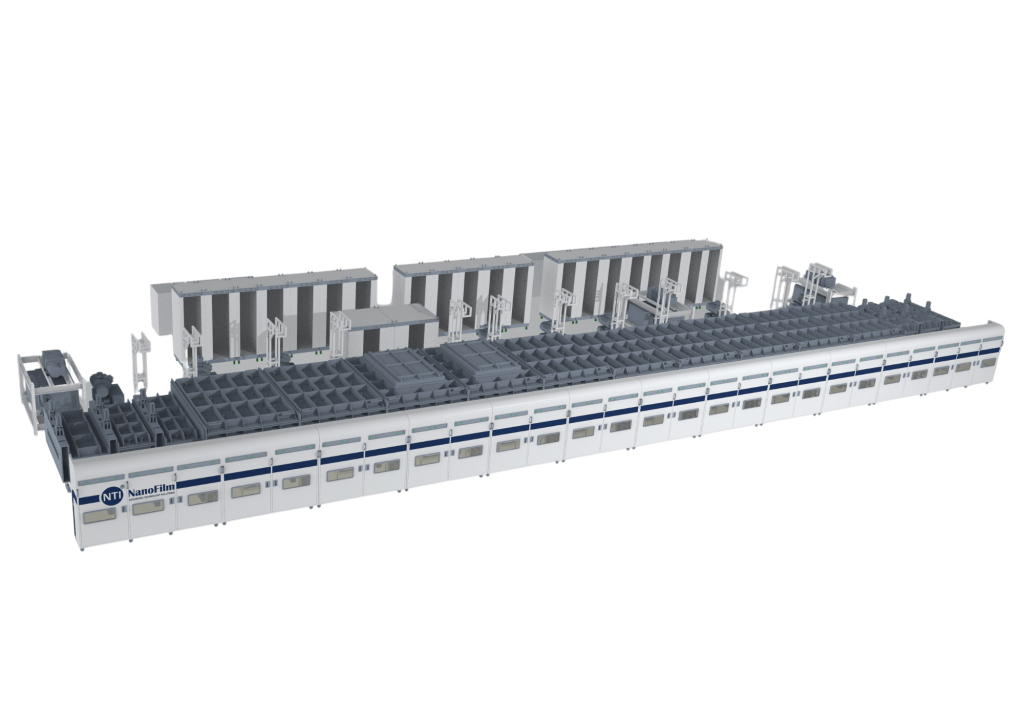

What are the main advantages of Nanofilm coating equipment?

We have been engineering, designing, and manufacturing vacuum coating / physical vapor deposition (PVD) / thin-film coating equipment for over 25 years and are a leader in the field. We are an integrated player providing both coating equipment and coating services. Our experiences in coating services provide first-hand knowledge that translate to state-of-the-art equipment that fit your production needs. We are your one-stop partner that provide equipment, deposition source materials, vaporization source, spare parts and after sales services.

-

What are the vaporization methods of your coating equipment?

Our equipment portfolio includes ion-beam, magnetron sputtering, filtered cathodic vacuum arc (FCVA) PVD vaporization method. The filtered cathodic vacuum arc (FCVA) is our proprietary technology, a plasma-based vaporization method that provide better control and more uniformed coating on a wide range of substrates.

-

What substates can your coating equipment coat?

Our equipment can coat a wide range of substrates including metal (stainless steel, copper, aluminium), alloy, polymer (plastic), ceramics.

-

What is the substrate maximum size?

We provide coating equipment with chamber size as big as 1.5m x 1.5m. The maximum size of substrate depends on the shape. Please get in touch with us to learn more.

-

What type of coating can your equipment coat?

Our equipment can coat diamond-like coating, optical filter coating, anti-reflective coating, conductive coating, and hydrophobic coating, multi-layer composite coating.

-

What is your lead time?

Lead time varies depending on your specification. Please get in touch to learn more.