- 12 Aug, 2025

Why Piston Rings Are a Critical Component to Marine Engine Reliability

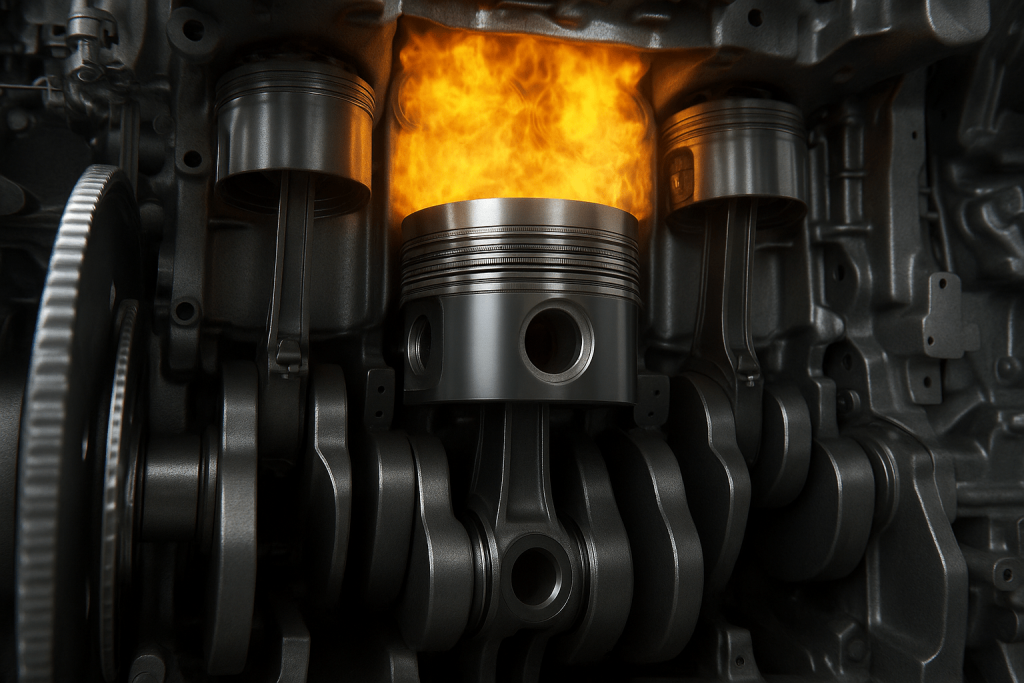

In the marine industry, engine reliability is non-negotiable. Whether it's a container ship crossing oceans or a coastal vessel navigating tight schedules, unexpected engine failure can lead to severe financial, operational, and safety consequences. Among the many components that keep a marine engine running, the marine piston ring stands out as the leading cause of marine engine breakdowns due to wear, scuffing, or loss of sealing. Its role is central to maintaining performance, and when it fails, the consequences ripple across the entire operation.

Challenges Faced by Marine Piston Rings

Piston rings in 2-stroke and 4-stroke marine engines endure some of the harshest mechanical and thermal conditions in any internal combustion engine. They operate under extreme pressure, high temperatures, corrosive exhaust gases, and constant metal-to-metal contact with the cylinder liner.

When piston rings begin to fail, whether due to scuffing, distortion, or wear, it sets off a chain reaction:

- Loss of combustion chamber seal → reduced power output

- Increased friction and oil consumption → higher fuel costs

- Surface fatigue and liner scoring → eventual engine seizure

In fact, excessive piston ring and cylinder liner wear remains the leading cause of marine engine breakdowns. The result? From up to 24 hours of ship repair and over $100,000 in direct costs, to voyage delays, lost revenue, and contractual penalties. In some cases, scheduled overhauls may require up to 3 weeks of vessel downtime, including the costly and complex process of cutting open the hull for engine removal. This kind of downtime directly impacts a vessel’s competitiveness and safety.

Limitations of Conventional Coatings

Traditionally, marine engine piston rings are protected using coatings such as electroplated ceramic chrome, hard chrome, nickel plating, thermal spray cermet, or even CVD-deposited hydrogenated DLC (a-C:H). While effective in earlier engine designs, these coatings are reaching their limits in today’s operating environment.

Modern marine engines demand:

- Lower friction for improved fuel efficiency

- Higher durability to withstand extended service intervals

- Better oil compatibility under new lubricant formulations

- Compliance with IMO regulations such as the upcoming global shipping carbon pricing mechanisms as part of its 2050 Net-zero GHG emissions targets

Unfortunately, many conventional coating methods struggle to maintain seal integrity or remain stable at high operating temperatures. As a result, ship operators face mounting costs and stricter compliance hurdles.

The i-TAC® Coating Breakthrough from NTI Nanofilm

Introducing i-TAC®, NTI Nanofilm’s proprietary ta-C coating applied via Filtered Cathodic Vacuum Arc (FCVA) technology. Engineered specifically for extreme applications like marine piston rings, i-TAC® offers next-level performance:

- 2.7× harder than standard PVD-DLC coatings

- 12× longer part lifespan

- 28% lower friction

- Thermal stability up to 600°C

Unlike traditional hydrogenated coatings, i-TAC®'s hydrogen-free ta-C layer delivers exceptional wear resistance and compatibility with modern engine oils. It forms an ultra-dense, defect-free barrier that protects against scuffing, micro-cracking, and seal degradation, ensuring marine engines operate at peak reliability.

Securing Future Marine Operations

As environmental regulations tighten and operating costs rise, upgrading to advanced coating solutions is no longer optional, it’s essential. Marine piston rings may be small components, but with the right surface engineering, they can drastically reduce downtime, cut fuel costs, and extend engine life.

Stay ahead of tightening regulations and rising operational costs. Upgrade your marine piston rings with i-TAC® coating solution.

Contact NTI Nanofilm to explore how our advanced coatings ensure marine engine reliability.