In today's era of growing environmental awareness and sustainability concerns, Nanofilm has demonstrated a strong commitment to energy conservation. Our coating process uses vacuum and high voltage to transfer target materials onto the substrates; and energy is required to achieve the desired quality. Recognising the high energy consumption in our coating process and the importance of reducing our carbon, we have made significant strides in promoting energy-efficient practices within our operations.

Key Highlights of what we have done to conserve energy:

Shutting Down When Not in Use

We have implemented an ‘OWN’ (Off When Not-in-use) initiative which enforces our production to shut down the coating machines in between coating batches. When each batch completes its coating cycle, the unloading – cool down – loading process in between the next batch would typically take about 2 hours. With OWN, we have successfully reduce the idling energy consumption of our equipment contributing to reduction of over 10% of our production energy consumption.

Use of Energy Efficient Inline Machines, Chillers and Compressors

We also increased the use of our proprietary inline machines, which are more energy efficient as they have the load-lock mechanism, reducing the need for vacuum pumping. Inline machines can be up to 20% more energy efficient than traditional batch machines.

Since the setup of Shanghai Site 2, with our greater scale, Nanofilm has been shifting to more efficient chillers and compressors, contributing to energy consumption reduction and further reduced our GHG emissions eventually.

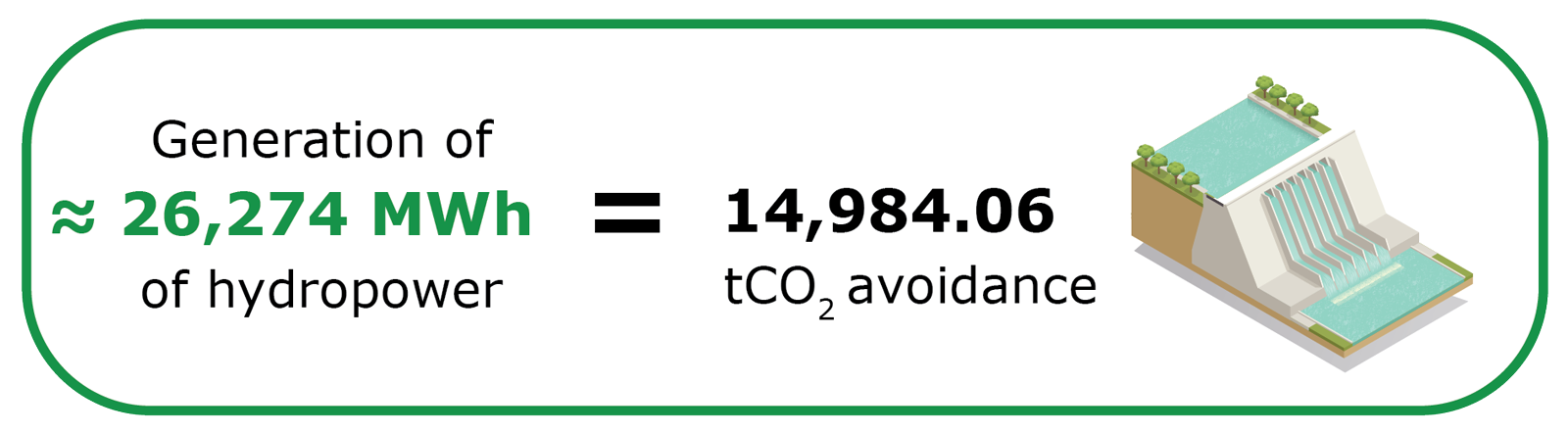

Hydropower

Since January 2023, we have switched to hydropower in our Shanghai plants as one of the initiatives to utilise clean electricity for our production. With hydropower, we have successfully converted the power supplied to our coating machines to one that is renewable. For the period of May to August 2023, we have utilised approximately 26,274 MWh of clean electricity, and this has contributed to 14,984.06 tCO₂ avoidance.

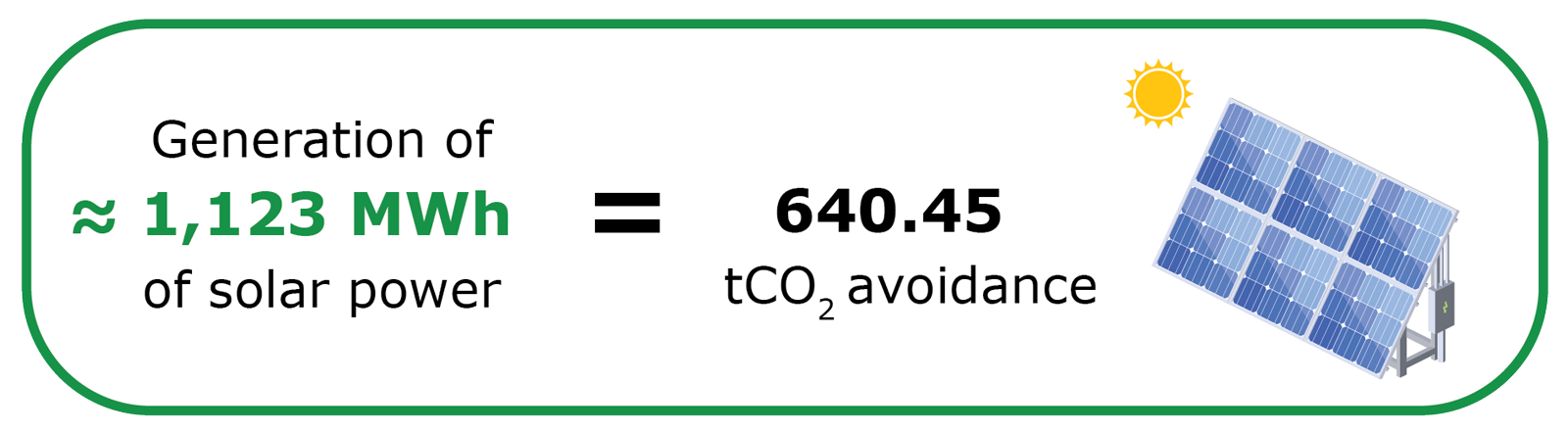

Solar Power

Staying true to our commitment, Nanofilm is also taking steps to implementing renewable energy throughout our production plants. Starting with Shanghai, we have successfully installed solar panels on the roofs of both plants, spanning a total of 19,000 m² at 0.9 MW and 1.47 MW respectively. Since implementation, the solar panels have generated approximately 1,123 MWh of electricity, which is equivalent to 640.45 tCO₂ avoidance. We are also accelerating for the installation of solar panels in Singapore HQ and Vietnam.

With the current initiatives, we are pleased to say that Nanofilm has established an all-round renewable energy solution for our operations in Shanghai and we strive to continually improve our processes across the globe.