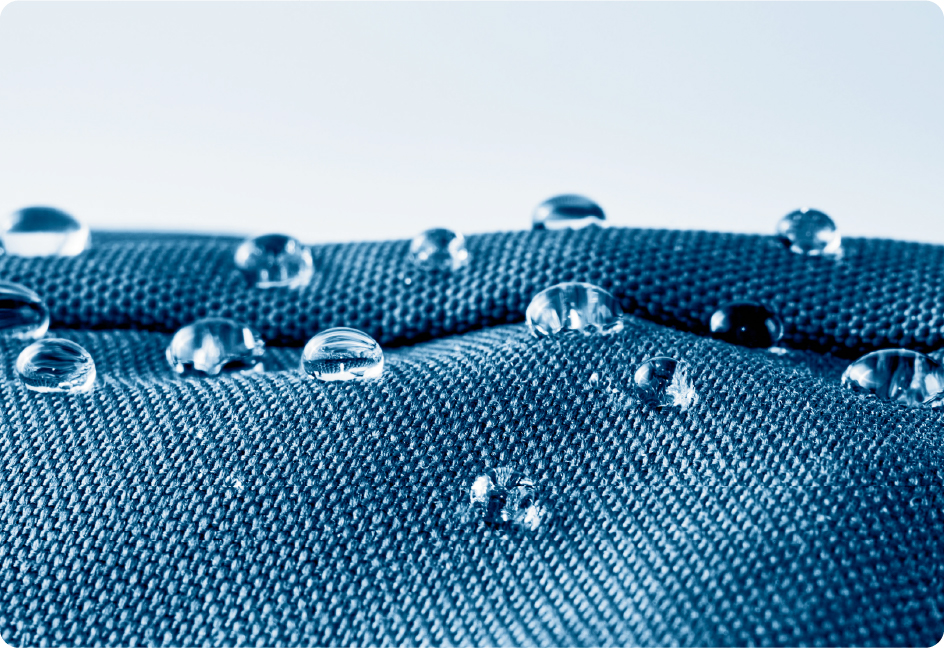

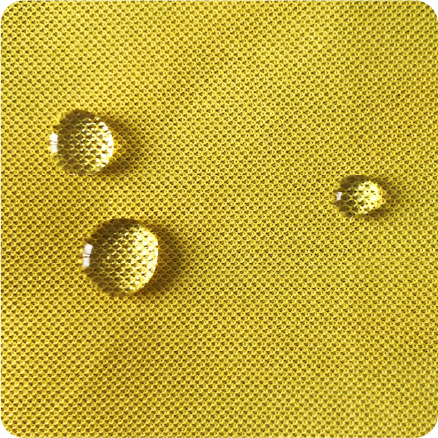

Deliver Superior Hydrophobic Protection for Products

Our hydrophobic coating uses PECVD and FCVA technologies to deposit a nano layer on textiles, polymers, and metals. This thin film lowers surface energy, increases water contact angle, and creates a durable hydrophobic barrier that prevents humidity and leakage, extending product lifespan.

Compared to traditional hydrophobic treatments, our vacuum coating technology enables flexible batch-size processing for diverse materials and applications.

Get In Touch