-

FCVA

Excellence coating

performance -

Carbon or Metal

SourceExtend coating types

-

Ion Beam

or SputteringFlexible configuration

-

Separate Vacuum

ChambersMinimise vacuum

pump waiting time -

Rotating Substrate

HolderAllows angle tilt

-

User Friendly

Control PanelEasy to operate and control

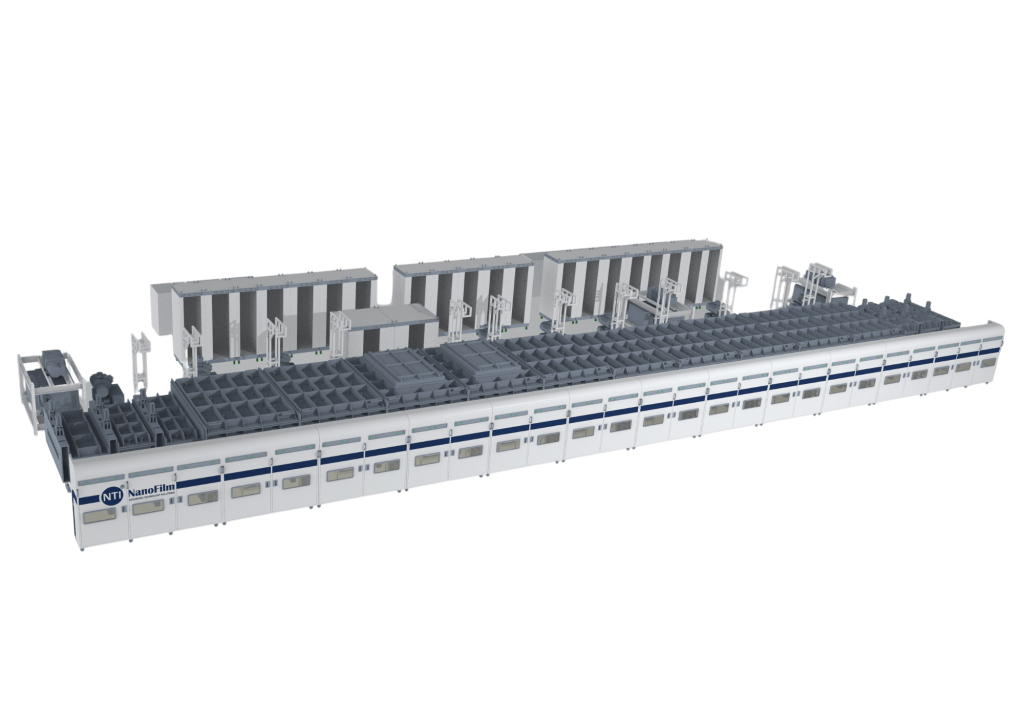

FCVA Load Lock Coating System for Optical and Precision Molds

The FCVA Load Lock Coating System features separate load and deposition chambers to reduce vacuum cycle time and prevent contamination. Designed for particle-free coating of glass lens molds and precision components, it supports both carbon and metal sources. Using our proprietary TAC-ON® materials, this advanced mold coater delivers ultra-smooth Diamond-Like Carbon (DLC) coatings trusted by leading global optical lens manufacturers for superior hardness, adhesion, and performance.

Get a Quote