Conductive Corrosion-Resistant Coating Solutions

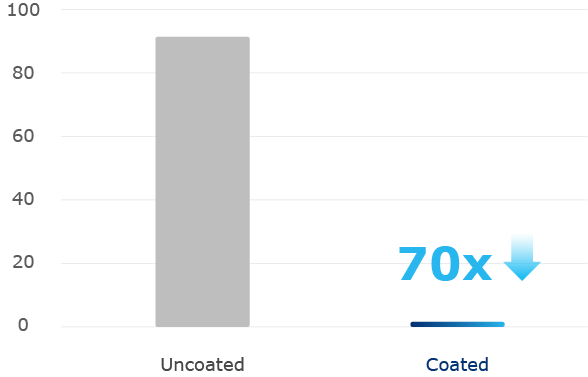

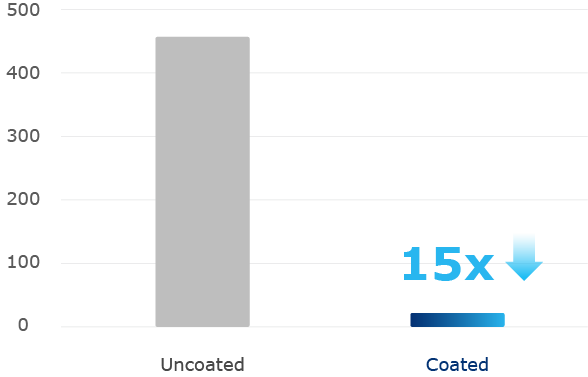

Our conductive corrosion-resistant coating uses non-hydrogen carbon and metal sources deposited through eco-friendly FCVA and sputtering technologies. This advanced PVD solution forms a dense protective layer on stainless steel, aluminum, and red copper components, significantly reducing corrosion current, extending service life, and improving electrical performance.

This coating provides a sustainable alternative to electroplating, eliminating hazardous chemicals and reducing environmental impact through advanced vacuum coating technology.

Get In Touch