-

Safe & Environmentally Friendly

Safe and environmentally friendly, as it almost produce no harmful chemical residuals.

-

Excellent

PerformanceProduce harder and more corrosion resistance thin film, with good impact strength, excellent scratch and abrasion resistance.

-

Extended Coating

PortfolioAble to utilize wide range of inorganic and some organic coating materials on a diverse group of substrates.

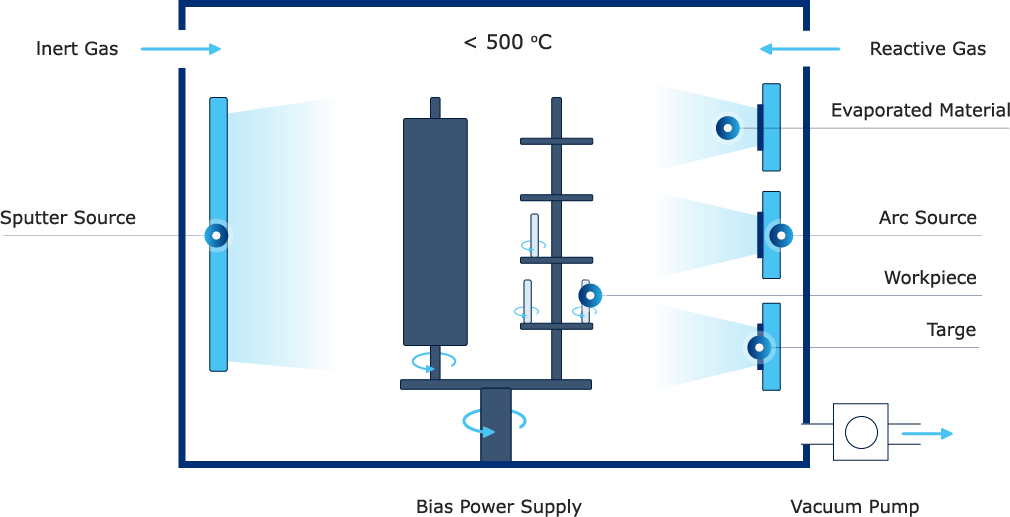

Physical Vapour Deposition (PVD) Technology

PVD is a dry surface treatment process, a method of thin film deposition, that ejects material from a "target" source in solid form onto a "substrate“ in vacuum. The process is safe and environmentally friendly with three simple steps: Vapourisation of the source using sputtering, cathodic arc or electron beam; transport the source material in gas form to substrate surface; nucleation and growth of the source material to produce thin film on the surface of substrate.