-

What is FCVA coating and how does it differ from standard PVD?

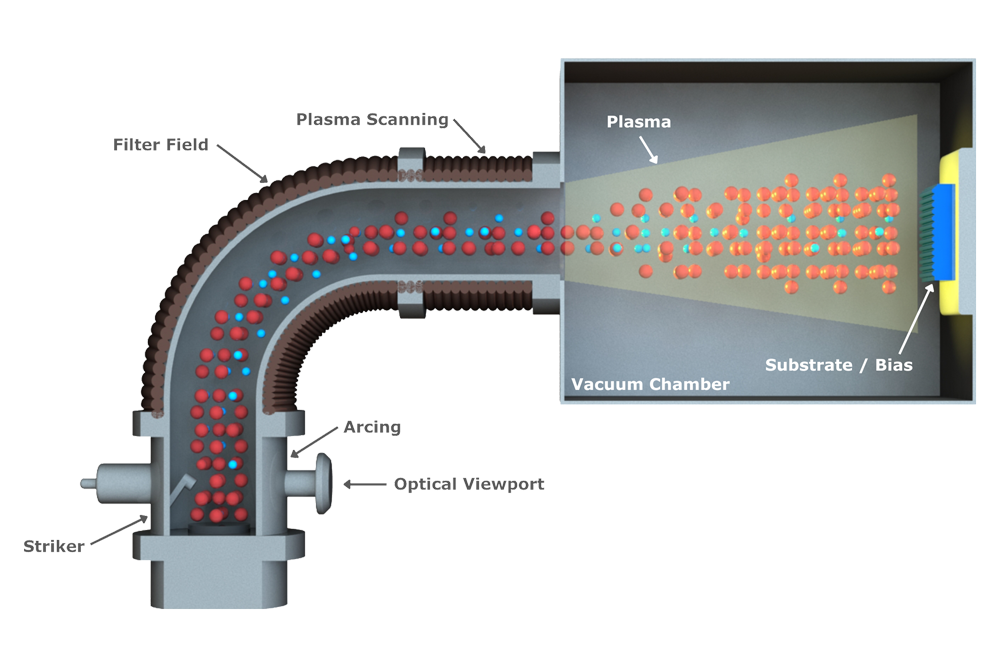

Filtered Cathodic Vacuum Arc (FCVA) coating is an advanced form of physical vapor deposition (PVD) that uses a cathodic arc to generate highly ionized plasma and then passes it through a magnetic filter to remove large droplets or macro-particles. This process produces an ultra-dense, smooth, and defect-free thin film with stronger adhesion, higher hardness, and lower friction than conventional sputtering or standard arc PVD coatings. Because of its high ion energy and clean deposition process, FCVA delivers coatings with excellent uniformity, superior wear resistance, and longer service life, making it a preferred technology for industries demanding precision and durability, such as semiconductor, optics, and automotive manufacturing.

-

What substrates and applications are suitable for FCVA coatings?

FCVA coatings can be applied to a wide range of substrates including metals, ceramics, polymers, and composites, due to their ability to form strong adhesion at both high and low temperatures. This makes FCVA ideal for precision tooling, glass lens molds, die-casting inserts, semiconductor cavity bars, and automotive engine parts, among many others. The technology is also used for decorative and functional surfaces in electronics, luxury goods, and optics where both performance and appearance matter. Because FCVA generates a dense and adherent coating layer even on complex shapes, it is especially effective for enhancing surface hardness, reducing friction, and preventing corrosion or wear under harsh environments.

-

What are the main performance benefits of FCVA coatings compared to other methods?

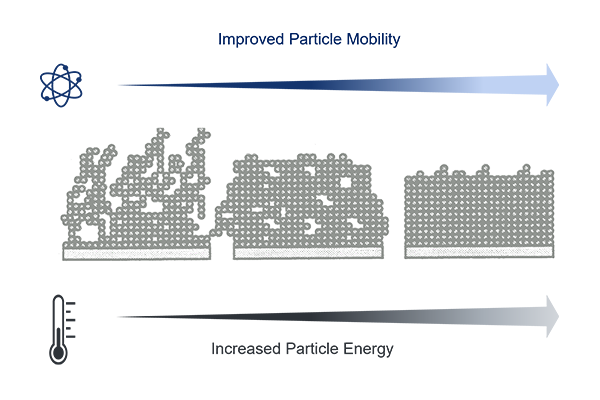

The performance benefits of FCVA coating stand out clearly against traditional PVD methods. FCVA produces ultra-dense, smooth films with minimal pinholes or voids, ensuring superior barrier and mechanical properties. The filtered arc plasma also gives exceptional coating adhesion, enabling better load resistance and long-term durability. Another key advantage is high coating hardness, which enhances tool life and wear resistance in cutting, molding, and automotive parts. FCVA operates with lower substrate heating, allowing deposition on temperature-sensitive materials like polymers and non-metallic surfaces. Most importantly, the process yields clean, droplet-free surfaces for consistent optical and decorative finishes, which cannot be achieved by standard arc PVD or magnetron sputtering systems.

-

What are the limitations or challenges when using FCVA coating systems?

Although FCVA coating provides exceptional quality, it comes with several engineering and economic considerations. The equipment cost and system complexity are typically higher due to the need for magnetic filtering chambers and precise plasma control. While the filtering process greatly reduces macro-particles, strict process control is still necessary to maintain surface cleanliness. Because of its high plasma energy and low deposition rate, achieving thick coatings can take longer time compared to simpler PVD methods. Additionally, target material and process recipe optimization are crucial since not all materials behave identically under arc plasma. However, for users requiring premium coating density, high adhesion, and defect-free surfaces, these challenges are often outweighed by the performance gains and product lifetime benefits of FCVA technology.

-

How to select or specify an FCVA coating for your application?

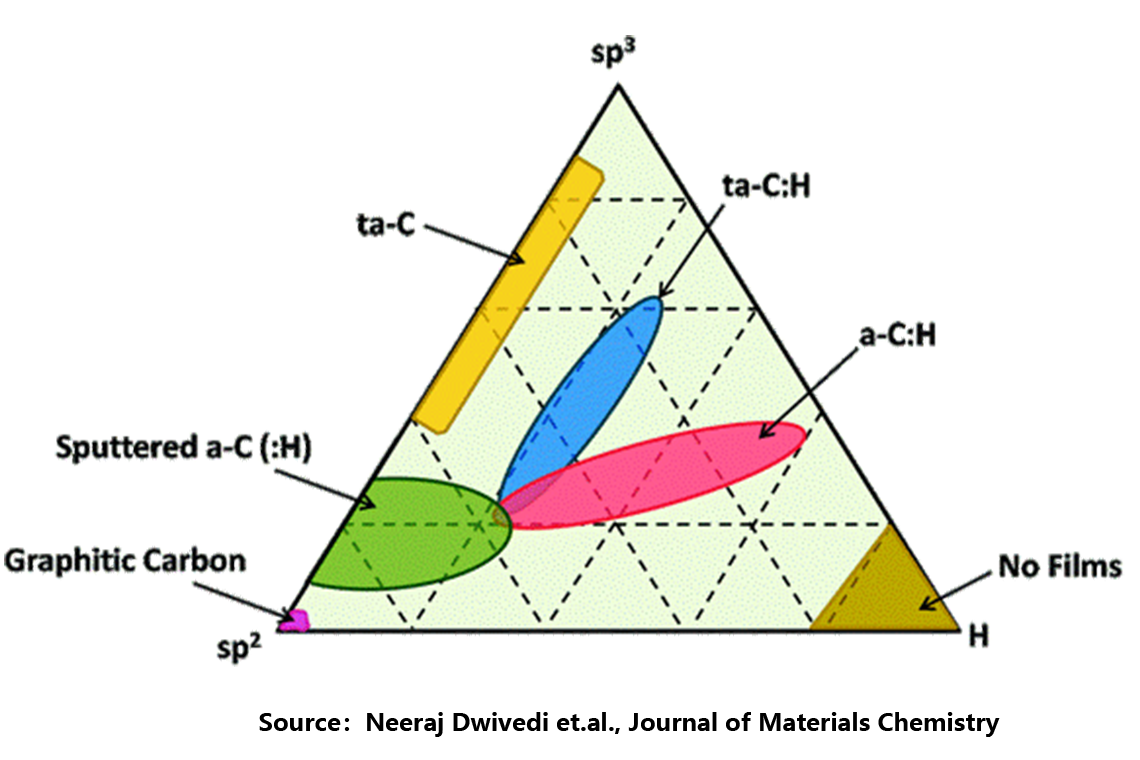

Selecting the right FCVA coating involves evaluating several key parameters to match your part’s functional and economic requirements. Start by considering the substrate type and its thermal tolerance, followed by the coating composition, for example, ta-C for ultra-low friction, TiN or TiSiN for hardness and wear resistance, or decorative FCVA coatings for luxury finishes. Define the film thickness and uniformity needed, as FCVA can produce coatings with very tight tolerance across complex geometries. You should also specify adhesion, hardness, and friction requirements according to ISO or ASTM test standards, ensuring consistent results in production. Finally, review the coating supplier’s equipment, process stability, and after-sales service, as FCVA coating quality depends heavily on process control and maintenance. A properly specified FCVA coating can deliver superior durability, aesthetic consistency, and cost efficiency over its lifetime compared to conventional PVD coatings.