Extend Metallurgy Mould Lifespan with TAC-ON®

Metal injection moulding form metal power into high precision components with near net shape, good dimensional precision pieces without the need of machining.

The moulding process is done with high pressure and high temperature, can cause damage to the mould, result in reduced mould’s life space and defects on the parts.

Extend MIM Life Span with TAC-ON® coating

| Coating |

TAC-ON® |

| Coating Material |

TAC |

| Hardness | 2500HV – 4000HV |

| Coating Thickness |

Ferroalloy mould: 1.5 – 2.0 µm

Tungsten alloy mould: 0.7 – 1.0 µm |

| Deposition Temperature |

<100°C |

The TAC-ON® coating thickness can be adjusted to forms a super hard and smooth layer on the surface of the mould without impairing precision, with low surface energy that reduces stickiness and friction, greatly improve the life span of the piece.

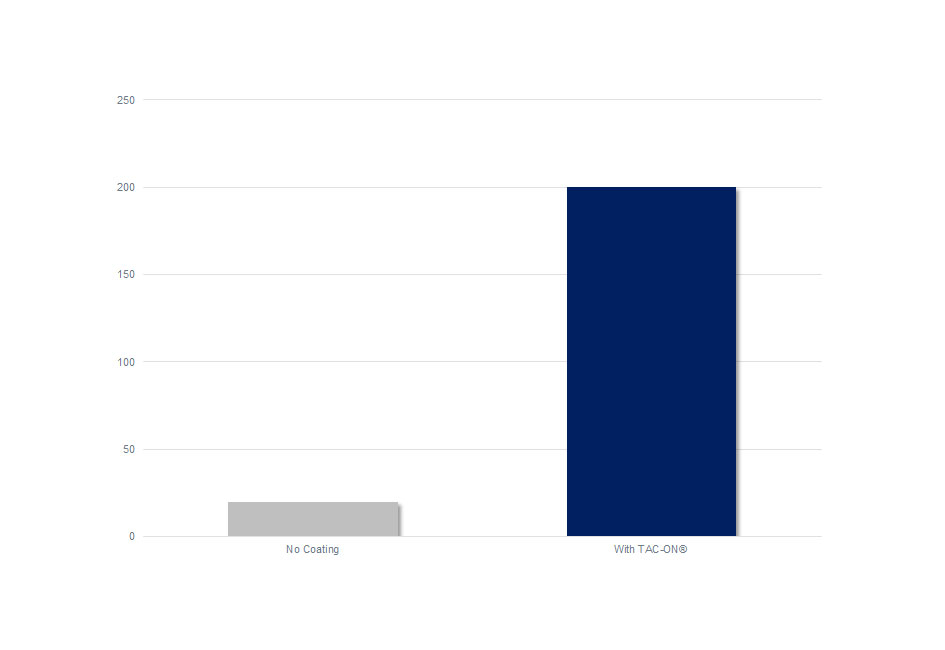

Life Span (K Times Injection)

Do you have any question and want to know more about our services? We will be glad to support you.