AR Coating Solutions Enhance Product Performance and Quality

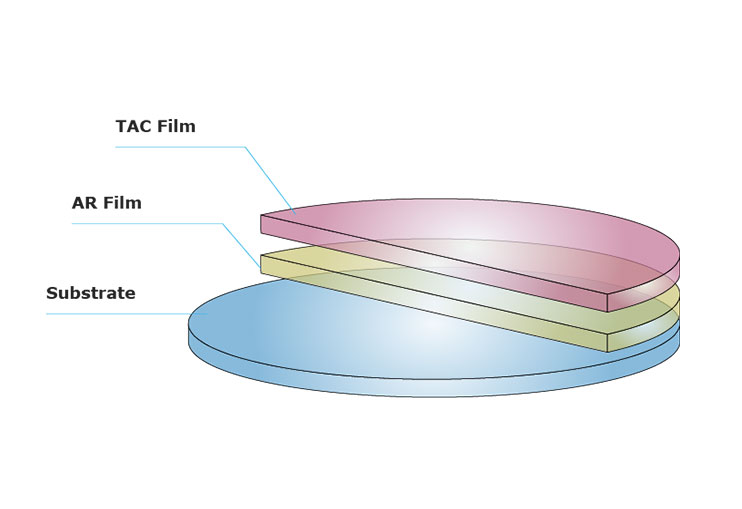

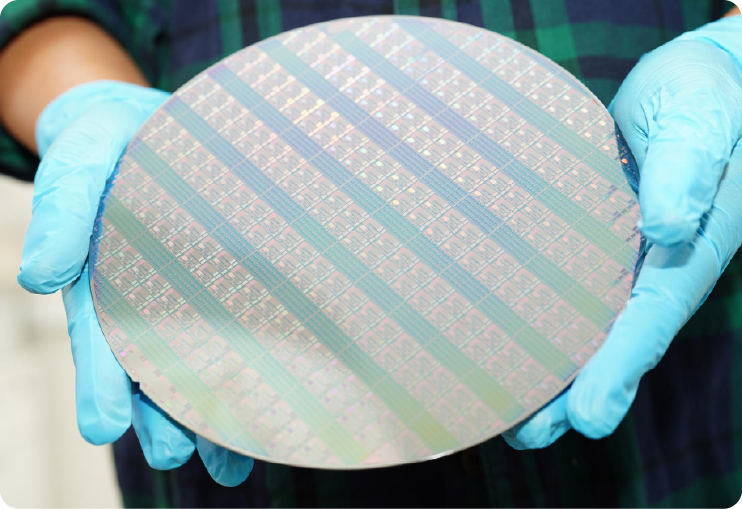

Our AR coating solution applies a thin film on quartz, chalcogenide, and other glass types using ion-beam and sputtering technology to achieve optimal surface hardness, optical reflectance, and transmission for enhanced product performance.

Get In Touch