-

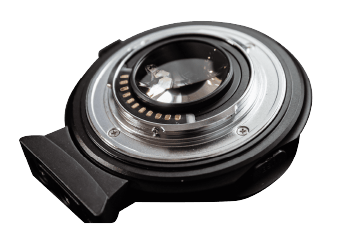

Adhesive Wear

-

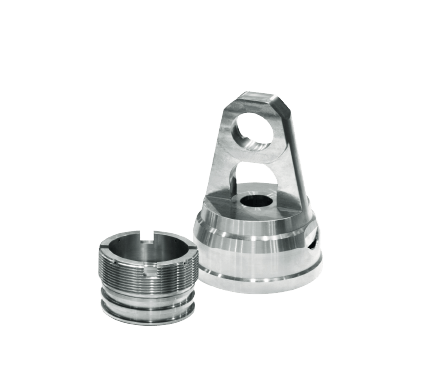

Abrasive Tear

-

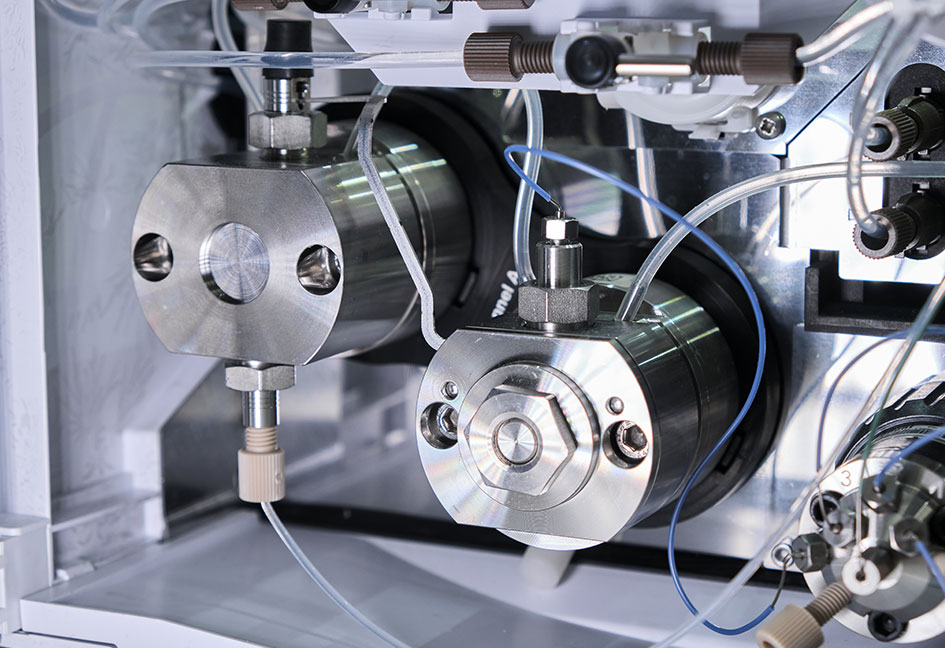

Corrosion

-

Surface Fatigue

Revolutionary Wear-Resistant Coating Solution for High Performance

TAC-ON® and i-TAC® coatings utilize patented FCVA technology to deposit non-hydrogenated carbon and composite materials at low temperatures, delivering superior hardness, adhesion, and smoothness compared to conventional DLC coatings. These advanced wear-resistant coatings minimize friction, reduce component wear, and extend product lifespan across industries such as electronics, semiconductor, precision engineering, printing, imaging, medical devices, and textile manufacturing.

Get In Touch