- Mobile Phone

- Smart Watch

-

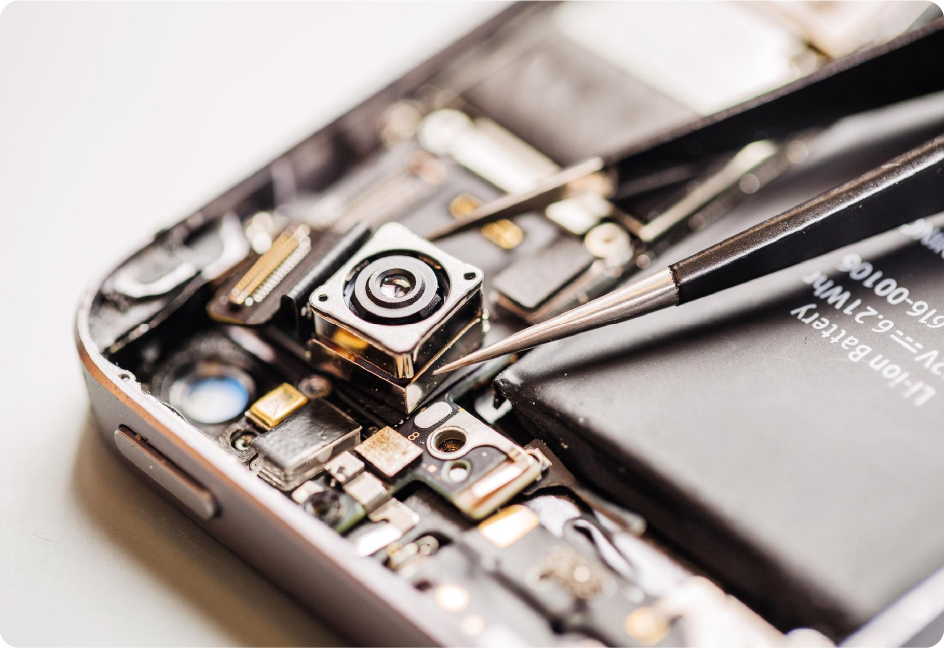

Phone Interior Components

-

Mobile Phone Camera Backplate

Feel free to contact us to customise your product solution. Contact Us

-

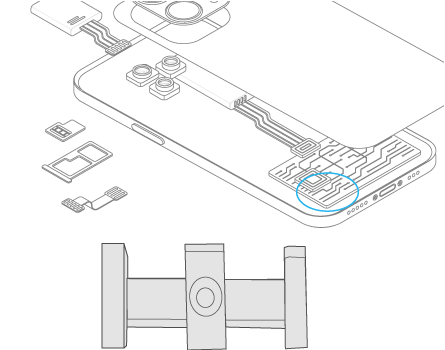

Spring Bar

Feel free to contact us to customise your product solution. Contact Us