FCVA Enables Highly Adjustable Coatings

FCVA enables highly adjustable coatings for optimal Diamond and Graphite-like properties, enables dense and uniform coatings

-

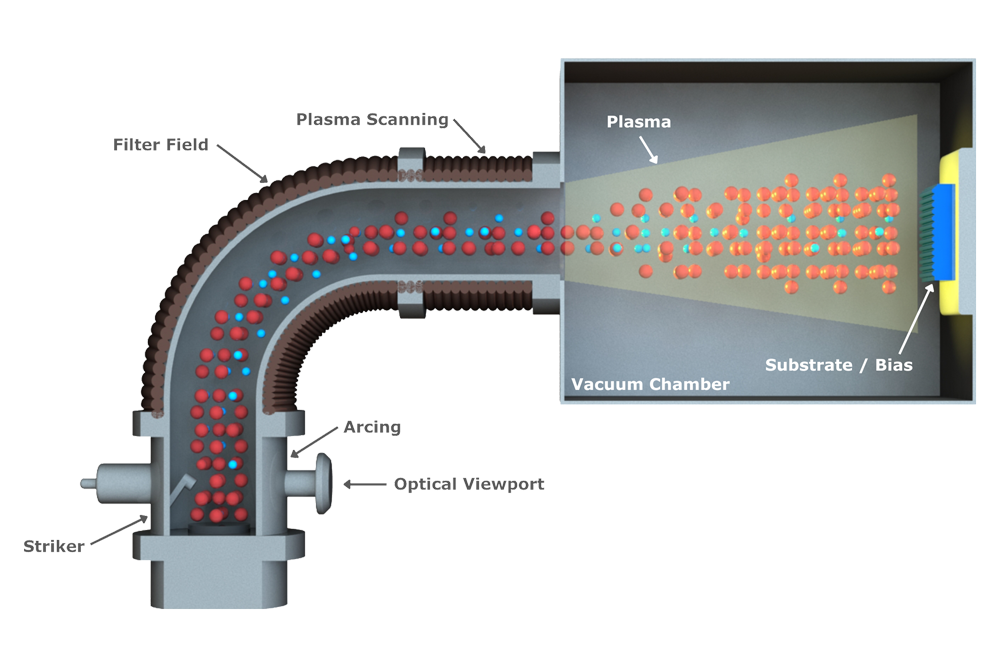

Curved Magnetic Field Filters Out Impurities for Particle-Free Coatings

- Particles trapped in the bend enable pure high-energy ion deposition, forming cleaner and denser coatings.

-

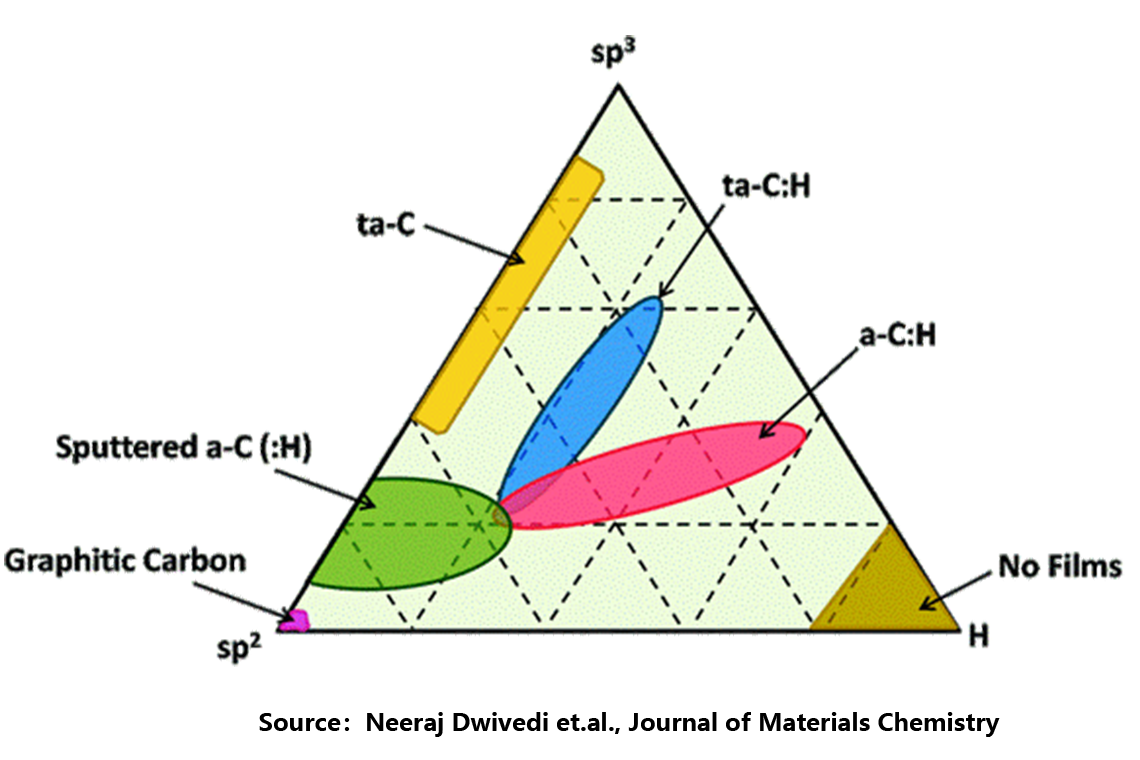

Tunable Diamond-like and Graphite-like Structures for Optimal Performance

-

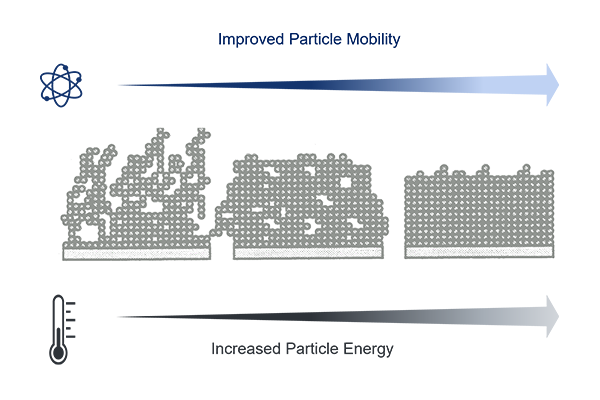

High Energy Ions Deliver Superior Density and Adhesion